Düzce TURKEY

Düzce TURKEY

We make quality and durable welds with our 0.9mm-15mm professional international welding certified masters.

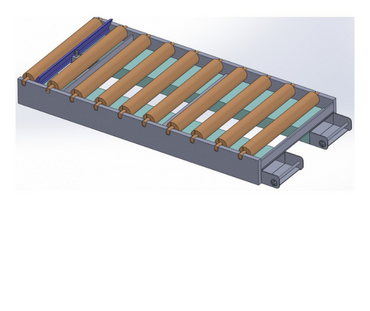

In the welded joints in the picture, the material type is st 37 6 mm.

Project-based platform carrier leg, all manufacturing belongs to us

Gas Submersible MIG/MAG Welding;

machine manufacturing

welded joint

construction